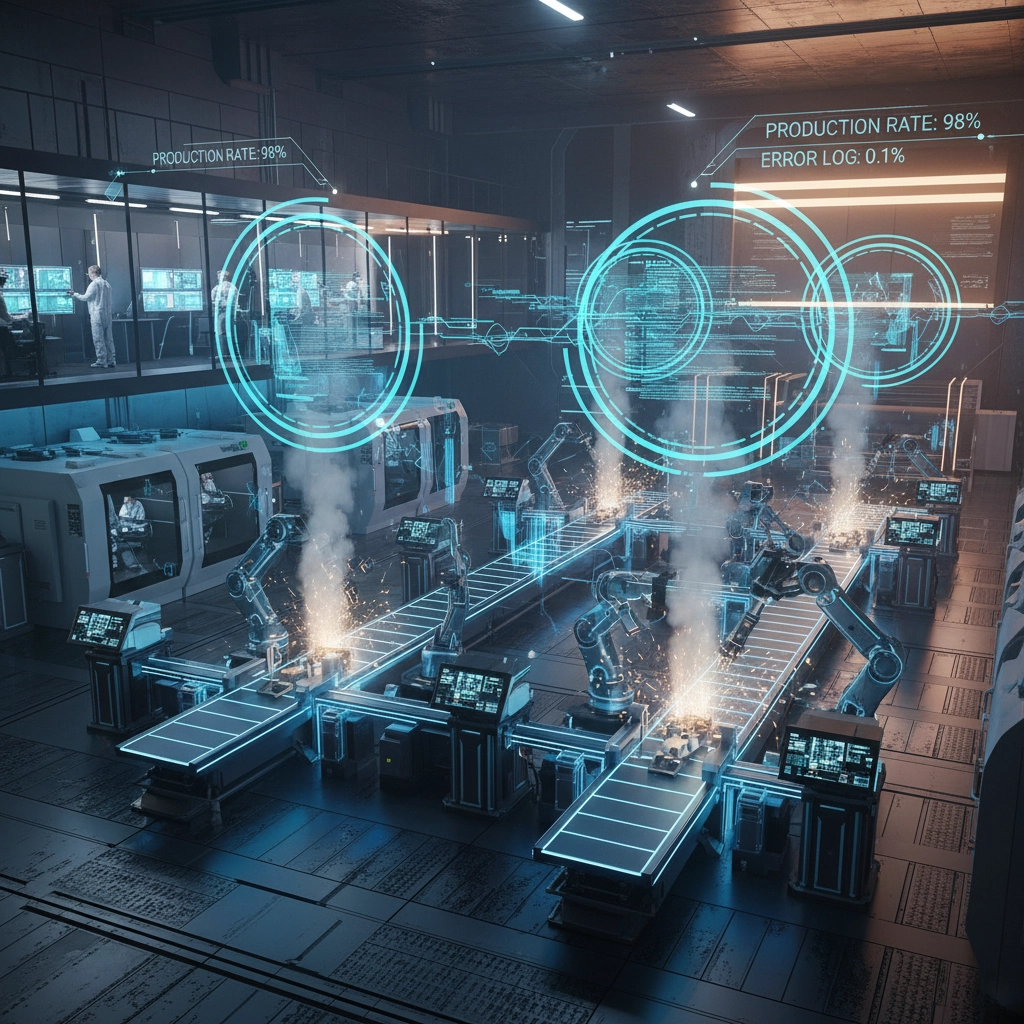

Manufacturing companies in 2026 face unprecedented pressure to optimize production efficiency while managing rising costs and skilled labor shortages. Smart factories that leverage automation for real-time production monitoring consistently outperform traditional facilities by 20-35% in overall equipment effectiveness (OEE). This comprehensive guide demonstrates how n8n automation can transform your manufacturing operations through intelligent production monitoring workflows.

Why Manufacturing Automation is Critical in 2026

Modern manufacturing environments generate massive volumes of sensor data from equipment, production lines, and quality control systems. Without automated monitoring, critical issues often go undetected until they cause expensive downtime or quality failures. Manual production monitoring simply cannot keep pace with the speed and complexity of today's manufacturing operations.

The average manufacturing plant experiences 800 hours of unplanned downtime annually, costing between $50,000 to $100,000 per hour depending on the industry. Automated production monitoring systems can reduce this downtime by up to 50% through early anomaly detection and predictive maintenance alerts.

Understanding n8n for Manufacturing Operations

n8n provides a visual, no-code automation platform that connects disparate manufacturing systems without requiring extensive programming knowledge. Unlike traditional industrial automation software that requires specialized expertise, n8n enables manufacturing engineers and operations teams to build sophisticated monitoring workflows using an intuitive drag-and-drop interface.

The platform's strength lies in its ability to integrate with virtually any system through APIs, webhooks, databases, and messaging protocols commonly used in manufacturing environments including MQTT, OPC UA, Modbus, and industrial ethernet protocols.

Step-by-Step Production Monitoring Workflow Setup

Step 1: Sensor Data Import Configuration

Begin by establishing data collection from your manufacturing sensors and equipment. Create an Interval node set to trigger every 30 seconds for continuous monitoring. Connect this to HTTP Request nodes configured to pull data from your equipment APIs or databases.

For temperature sensors, configure the workflow to collect readings from multiple zones across your production floor. Set up separate data streams for pressure sensors, vibration monitors, and production counters. Each sensor type requires its own data parsing logic to handle different measurement units and formats.

Step 2: Data Processing and Validation

Add Function nodes to clean and validate incoming sensor data. Manufacturing environments often experience sensor noise, communication interruptions, and data formatting inconsistencies. Implement data validation rules that check for reasonable value ranges, identify missing data points, and flag potential sensor malfunctions.

Transform raw sensor readings into standardized formats that your monitoring dashboard can consume. This includes unit conversions, data aggregation for trend analysis, and calculated metrics like equipment efficiency ratios.

Step 3: Real-Time Dashboard Updates

Configure HTTP Request nodes to push processed data to your manufacturing dashboard system. Most modern manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms provide REST APIs for real-time data updates.

Set up parallel workflow branches to update different dashboard components simultaneously. Production metrics flow to operations dashboards, quality data updates quality control systems, and equipment status information feeds maintenance management platforms.

Step 4: Anomaly Detection Logic

Implement IF nodes with sophisticated conditional logic to identify production anomalies. Configure multiple threshold levels:

- Warning thresholds (yellow alerts) for conditions requiring attention but not immediate action

- Critical thresholds (red alerts) for conditions requiring immediate intervention

- Trend-based alerts that identify gradual degradation patterns over time

For temperature monitoring, set warning alerts at 5°F above normal operating range and critical alerts at 10°F above normal range. Production rate monitoring should trigger warnings when output falls 15% below target and critical alerts at 25% below target.

Step 5: Automated Alert Distribution

Configure alert routing based on severity levels and production shift schedules. Use Email nodes for standard notifications, SMS nodes for critical alerts, and webhook integrations with systems like PagerDuty or Microsoft Teams for escalated incidents.

Implement intelligent alert suppression to prevent notification floods during widespread system issues. Set cooldown periods to avoid repeated alerts for the same condition and configure alert escalation procedures that notify supervisors if initial alerts aren't acknowledged within defined timeframes.

Advanced Manufacturing Automation Features

Predictive Maintenance Integration

Extend your monitoring workflow to include predictive maintenance capabilities. Collect historical sensor data and identify patterns that precede equipment failures. Implement machine learning models that analyze vibration signatures, temperature trends, and production patterns to predict maintenance needs before breakdowns occur.

Configure automated work order generation that creates maintenance tickets in your computerized maintenance management system (CMMS) when predictive algorithms identify potential issues.

Quality Control Automation

Integrate quality control measurements into your production monitoring workflow. Connect inspection equipment, vision systems, and testing apparatus to automatically validate product quality throughout the manufacturing process.

Set up automated production holds when quality measurements exceed tolerance limits, and configure notification workflows that alert quality engineers to investigate anomalies.

Supply Chain Coordination

Extend monitoring workflows to coordinate with supply chain systems. Monitor inventory levels of critical materials and automatically trigger purchase orders when stock levels approach reorder points. Integrate with supplier systems to track incoming material quality and delivery schedules.

Real-World Manufacturing Use Cases

Automotive Component Manufacturing

A tier-1 automotive supplier implemented n8n automation to monitor injection molding operations across three production lines. The system monitors mold temperatures, injection pressures, and cycle times while automatically adjusting process parameters to maintain part quality.

When temperature deviations exceed 2°C from optimal settings, the system automatically adjusts heating element output and alerts operators to potential issues. This automation reduced defect rates by 40% and increased overall equipment effectiveness from 72% to 89%.

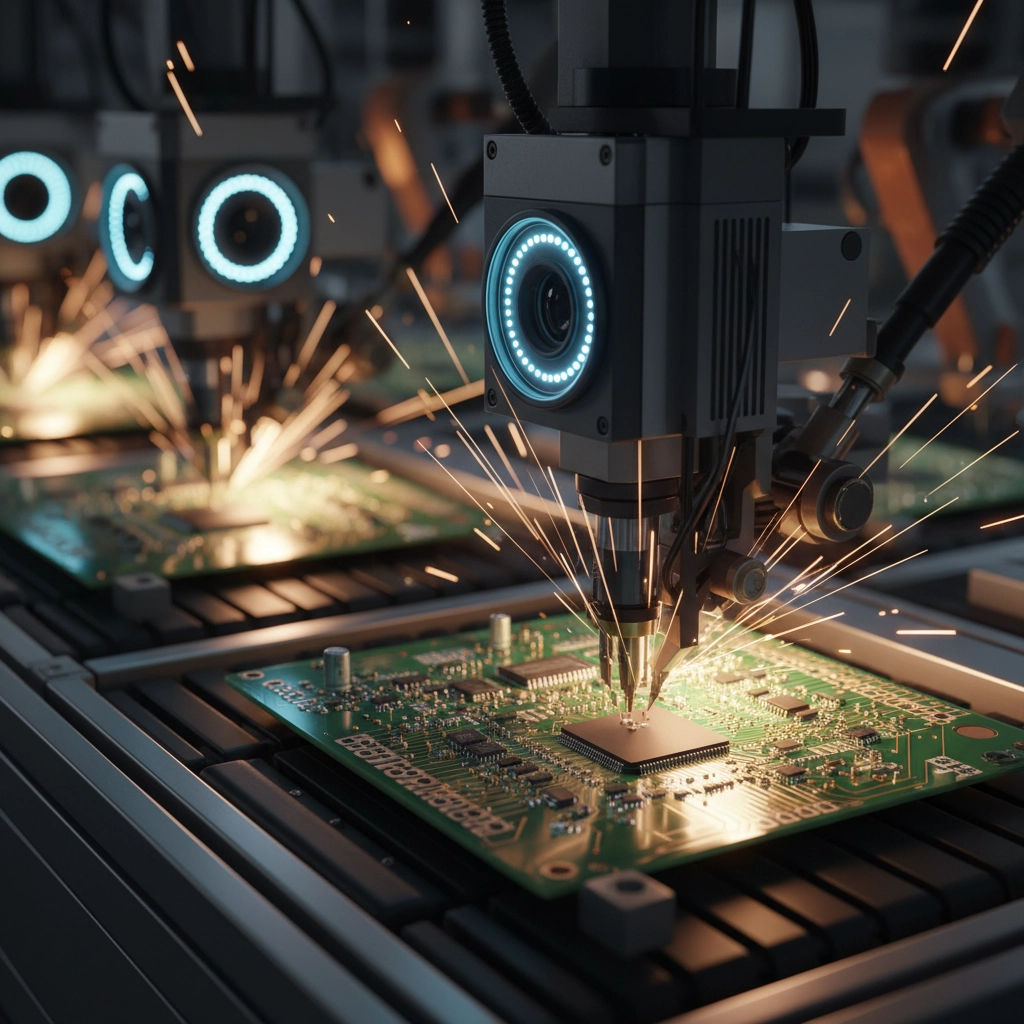

Electronics Assembly Operations

An electronics manufacturer uses n8n workflows to monitor surface mount technology (SMT) pick-and-place machines, wave solder systems, and automated optical inspection equipment. The system tracks placement accuracy, solder joint quality, and component inventory levels in real-time.

Automated alerts notify technicians when placement accuracy falls below 99.5% or when component feeders require replenishment. Integration with the manufacturing execution system automatically adjusts production schedules based on equipment performance and material availability.

Implementation Best Practices and ROI Optimization

Security and Compliance Considerations

Manufacturing automation systems must address cybersecurity concerns and regulatory compliance requirements. Implement role-based access controls within n8n to restrict workflow modification privileges. Use encrypted communication channels for all data transfers and establish audit trails for automation activities.

Ensure compliance with industry standards like ISO 27001 for information security and industry-specific regulations such as FDA 21 CFR Part 11 for pharmaceutical manufacturing.

Scalability Planning

Design workflows with scalability in mind from the initial implementation. Use modular workflow components that can be easily replicated across multiple production lines or facilities. Implement centralized configuration management to maintain consistent monitoring parameters across your manufacturing network.

Plan for horizontal scaling by distributing workflow execution across multiple n8n instances using queue mode for high-throughput environments.

Performance Monitoring and Optimization

Regularly monitor workflow performance using n8n's execution logs and error tracking capabilities. Identify bottlenecks in data processing and optimize database queries and API calls to maintain real-time responsiveness.

Implement workflow health monitoring that alerts administrators when automation systems experience performance degradation or failure conditions.

Measuring Automation Success

Track key performance indicators to demonstrate the value of your manufacturing automation investment:

- Reduction in unplanned downtime: Target 30-50% improvement within six months

- Increase in overall equipment effectiveness: Aim for 15-25% improvement

- Decrease in quality defects: Expect 20-40% reduction in defect rates

- Improvement in maintenance efficiency: Target 25% reduction in maintenance costs

- Enhanced operator productivity: Measure 10-20% increase in operator efficiency

Getting Started with Manufacturing Automation

Manufacturing automation represents a critical competitive advantage in today's industrial landscape. Companies that implement comprehensive production monitoring systems position themselves for sustained growth and operational excellence.

At Virtual Nexgen Solutions, we specialize in helping manufacturing companies implement intelligent automation workflows using n8n and other cutting-edge platforms. Our team of automation experts understands the unique challenges facing modern manufacturers and can design custom solutions that deliver measurable results.

Ready to transform your manufacturing operations with intelligent automation? Book a consultation with our automation specialists to discuss your specific production monitoring needs and develop a customized implementation strategy.

Schedule your free 30-minute automation assessment today and discover how Virtual Nexgen Solutions can help you achieve operational excellence through smart manufacturing automation.

Visit virtualnexgen.com to learn more about our comprehensive automation services and manufacturing solutions.