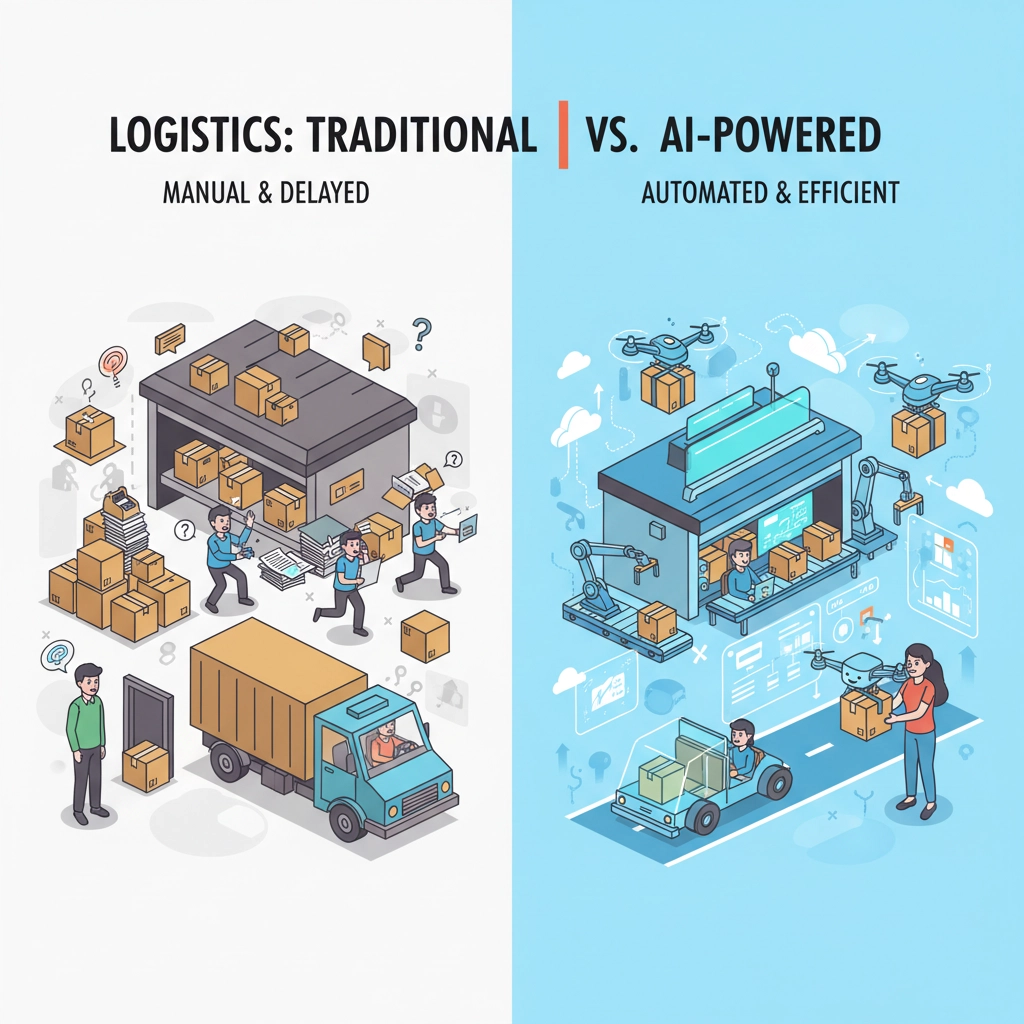

The logistics industry is experiencing its biggest transformation since the invention of the shipping container. In 2026, artificial intelligence isn't just a buzzword: it's the backbone of modern supply chains, revolutionizing everything from warehouse operations to last-mile delivery. Companies that embrace AI automation are cutting costs by 20%, boosting productivity by 40%, and creating supply chains that adapt in real-time to disruptions.

If you're running a logistics business and still relying on manual processes, you're not just falling behind: you're hemorrhaging money and customer satisfaction. Let's dive into how AI automation is reshaping the logistics landscape and the specific tools and processes that can transform your operations.

Why Logistics Companies Are Desperately Embracing AI Automation

The logistics industry faces unique challenges that make AI automation not just beneficial, but essential for survival. Rising fuel costs, driver shortages, increasing customer expectations for faster delivery, and unpredictable global disruptions have created a perfect storm that only smart technology can navigate.

Modern logistics operations generate massive amounts of data: shipment tracking, weather patterns, traffic conditions, customer preferences, and inventory levels. Human operators simply can't process this information fast enough to make optimal decisions. AI systems, however, can analyze millions of data points in seconds, predicting problems before they occur and optimizing routes in real-time.

Essential AI Automation Tasks Every Logistics Company Should Implement

1. Route Optimization and Dynamic Planning

What it automates: Traditional route planning that takes hours of manual calculation

Business impact: Reduces fuel costs by 15-25% and improves delivery times by 30%

Step-by-step implementation:

- Step 1: Install GPS tracking devices on all vehicles

- Step 2: Implement AI route optimization software like Route4Me or OptimoRoute

- Step 3: Connect your system to real-time traffic and weather APIs

- Step 4: Set up automated route recalculation triggers based on traffic conditions

- Step 5: Train drivers to use mobile apps that provide turn-by-turn optimized directions

Recommended tools: Route4Me, OptimoRoute, Workwave Route Manager

2. Intelligent Shipment Tracking and Predictive Delivery

What it automates: Manual package scanning and customer communication

Business impact: Reduces customer service calls by 60% and improves satisfaction scores

Step-by-step implementation:

- Step 1: Integrate IoT sensors on packages for real-time location tracking

- Step 2: Deploy Project44 or similar visibility platforms

- Step 3: Set up automated customer notifications via SMS and email

- Step 4: Configure predictive delivery windows using AI algorithms

- Step 5: Create automated exception alerts for delayed or at-risk shipments

Recommended tools: Project44, FourKites, Descartes MacroPoint

3. Automated Order Processing and Inventory Management

What it automates: Manual order entry, inventory counting, and reorder processes

Business impact: Reduces processing errors by 95% and cuts order fulfillment time by 50%

Step-by-step implementation:

- Step 1: Implement EDI (Electronic Data Interchange) connections with major clients

- Step 2: Deploy warehouse management systems like Manhattan Associates or SAP

- Step 3: Install RFID tags or barcode scanning systems for automatic inventory tracking

- Step 4: Set up AI-powered demand forecasting using historical data

- Step 5: Configure automated reorder points and supplier notifications

Recommended tools: Manhattan Associates, SAP Extended Warehouse Management, Oracle WMS

Advanced Warehouse Automation Technologies

Robotic Process Automation (RPA) for Warehouse Operations

Modern warehouses are transforming into intelligent hubs where robots work alongside human operators. Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) can sort, pick, and pack goods 24/7 with near-perfect accuracy.

Implementation process:

- Phase 1: Assess your current warehouse layout and identify bottlenecks

- Phase 2: Start with modular robotic systems that can be easily integrated

- Phase 3: Deploy AI-powered vision systems for product identification

- Phase 4: Implement robotic de-palletizing and pallet-building systems

- Phase 5: Scale up with additional robots as ROI is proven

Top robotic solutions: Amazon Robotics, Fetch Robotics, GreyOrange, Locus Robotics

Predictive Maintenance for Fleet Management

AI-powered predictive maintenance prevents costly breakdowns and extends vehicle life by analyzing engine data, driving patterns, and maintenance history.

Implementation steps:

- Step 1: Install telematics devices in all vehicles

- Step 2: Connect to predictive maintenance platforms like Samsara or Verizon Connect

- Step 3: Set up maintenance alerts based on AI predictions, not just mileage

- Step 4: Create automated work orders for predicted maintenance needs

- Step 5: Track performance improvements and cost savings

Industry-Specific AI Tools for Maximum Impact

For E-commerce Fulfillment Centers

- ShipBob: AI-powered fulfillment with predictive inventory placement

- Fabric: Micro-fulfillment automation for faster urban delivery

- Berkshire Grey: Robotic solutions specifically for e-commerce picking

For Cold Chain Logistics

- Sensitech: Temperature monitoring with AI-powered anomaly detection

- Controlant: Real-time cold chain visibility with predictive alerts

- Emerson Cargo Solutions: Automated temperature control systems

For Last-Mile Delivery

- Onfleet: AI-powered route optimization for delivery fleets

- Dispatch Science: Machine learning for delivery logistics

- LogiNext: End-to-end last-mile automation platform

Building Your AI Automation Strategy: A Practical Roadmap

Phase 1: Foundation (Months 1-3)

Start with data collection and basic automation. Implement GPS tracking, basic route optimization, and automated customer notifications. Focus on quick wins that provide immediate ROI.

Phase 2: Intelligence (Months 4-8)

Add predictive analytics and advanced automation. Deploy inventory management systems, predictive maintenance, and AI-powered demand forecasting.

Phase 3: Optimization (Months 9-12)

Integrate advanced robotics, machine learning algorithms, and autonomous systems. This is where you'll see the most dramatic improvements in efficiency and cost reduction.

Measuring Success: Key Performance Indicators

Track these metrics to ensure your AI automation investments are paying off:

- Delivery accuracy: Target 99.5% or higher

- On-time delivery rate: Aim for 95% or better

- Fuel cost per mile: Should decrease by 15-25%

- Order processing time: Target 50% reduction

- Customer satisfaction scores: Monitor and improve continuously

- Equipment uptime: Increase by at least 20%

The Future is Now: Don't Get Left Behind

The logistics companies thriving in 2026 aren't the ones with the biggest trucks or most warehouses: they're the ones with the smartest technology. AI automation isn't coming to the logistics industry; it's already here, and companies that delay implementation are losing market share to more agile competitors.

The global warehouse automation market is projected to reach $63.4 billion by 2030, with a compound annual growth rate of 16.2%. Companies using AI-powered logistics solutions report cutting costs and CO₂ emissions by up to 20% while boosting productivity by 40%.

Ready to Transform Your Logistics Operations?

Implementing AI automation in logistics doesn't have to be overwhelming. At Virtual Nexgen Solutions, we specialize in helping businesses navigate the complex world of AI automation, providing expert guidance and hands-on support to ensure successful implementation.

Our team of AI automation specialists has helped dozens of logistics companies reduce costs, improve efficiency, and stay competitive in an rapidly evolving market. We understand the unique challenges facing the logistics industry and can develop a customized automation strategy that fits your specific needs and budget.

Don't let your competition leave you behind. The logistics revolution is happening now, and the companies that act quickly will dominate their markets for years to come.

Ready to get started? Book a free 30-minute consultation with our AI automation experts at Virtual Nexgen Solutions and discover how AI can transform your logistics operations. Our specialists will analyze your current processes, identify automation opportunities, and create a roadmap for implementation that delivers measurable results.

Visit us at www.virtualnexgen.com to learn more about our comprehensive AI automation services and see how we're helping logistics companies across the country streamline their operations and boost their bottom line.

The future of logistics is automated, intelligent, and profitable. Make sure your company is part of it.