The manufacturing landscape is experiencing a seismic shift. By 2026, artificial intelligence isn't just changing how factories operate: it's completely redefining what's possible in production, efficiency, and profitability. With 81% of industrial executives planning to increase AI investments over the next three years, we're witnessing the transition from AI experimentation to AI execution as a core business necessity.

Manufacturing companies that embrace AI automation now are positioning themselves as industry leaders, while those who hesitate risk falling behind competitors who are already reaping the benefits of smarter, more efficient operations.

The Current State of AI in Manufacturing

Today's smart factories are leveraging AI automation to solve complex challenges that have plagued the industry for decades. From unpredictable equipment failures costing millions in downtime to supply chain disruptions that can halt production for weeks, AI is providing solutions that were previously impossible.

The shift toward "agentic AI": systems that can reason, plan, and take autonomous action: is transforming manufacturing from reactive problem-solving to predictive, self-optimizing operations. By 2027, 40% of all operational data will be integrated across applications and platforms autonomously through AI agents, creating unprecedented operational visibility and control.

Top 3 Manufacturing Tasks Perfect for AI Automation

1. Supply Chain Management Automation

The Challenge: Traditional supply chain management relies on historical data and manual forecasting, making it nearly impossible to predict and respond to disruptions in real-time.

AI Solution: Intelligent supply chain systems that analyze multiple data sources simultaneously: market trends, weather patterns, geopolitical events, supplier performance, and demand fluctuations: to optimize procurement, logistics, and inventory levels.

Step-by-Step Implementation Process:

Step 1: Data Integration Setup

- Connect all supply chain data sources (ERP, CRM, supplier databases, market feeds)

- Implement data cleaning and standardization protocols

- Establish real-time data streaming from suppliers and logistics partners

Step 2: AI Model Deployment

- Deploy predictive analytics models for demand forecasting

- Implement risk assessment algorithms for supplier evaluation

- Set up automated alerts for supply chain anomalies

Step 3: Automation Rules Configuration

- Create automated reorder points based on predictive analysis

- Establish supplier switching protocols for risk mitigation

- Configure dynamic pricing algorithms based on supply availability

Step 4: Continuous Learning Implementation

- Enable machine learning feedback loops from actual outcomes

- Regular model retraining with new market data

- Performance monitoring and optimization cycles

Recommended Tools:

- SAP Integrated Business Planning: Advanced supply chain planning with AI-powered insights

- Oracle Supply Chain Management Cloud: Real-time visibility and predictive analytics

- Blue Yonder (JDA): Machine learning-driven supply chain optimization

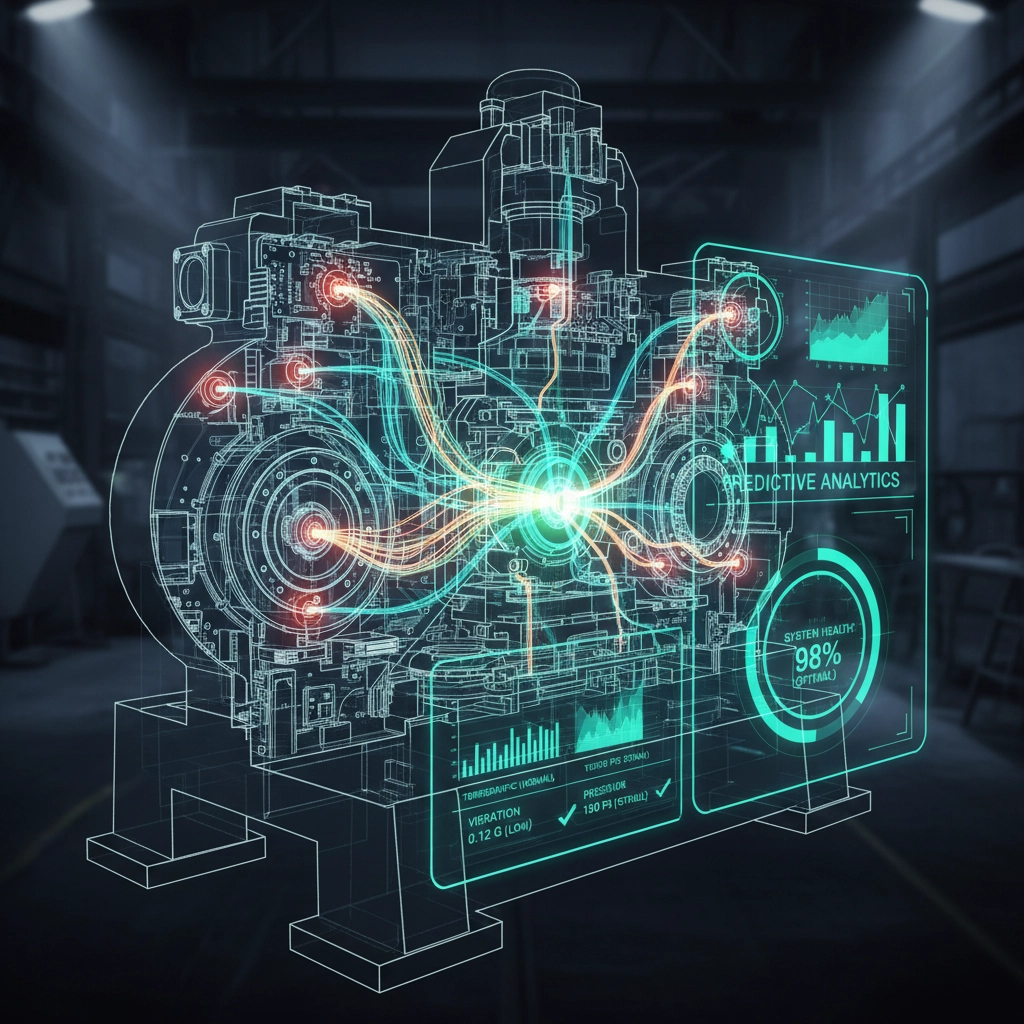

2. Predictive Maintenance Automation

The Challenge: Unplanned equipment failures cost manufacturers an average of $50 billion annually, with traditional maintenance strategies either too reactive or too costly.

AI Solution: Smart maintenance systems that continuously monitor equipment health, predict failures before they occur, and automatically schedule maintenance activities to minimize downtime.

Step-by-Step Implementation Process:

Step 1: Sensor Network Deployment

- Install IoT sensors on critical equipment (vibration, temperature, pressure, acoustic)

- Set up data collection infrastructure with edge computing capabilities

- Establish secure connectivity for real-time data transmission

Step 2: AI Analytics Platform Setup

- Deploy machine learning models trained on equipment failure patterns

- Configure anomaly detection algorithms for early warning systems

- Implement digital twin technology for equipment simulation

Step 3: Automated Workflow Creation

- Set up automatic work order generation for predicted maintenance needs

- Configure parts ordering systems triggered by maintenance predictions

- Establish automated scheduling integration with production planning

Step 4: Continuous Optimization

- Regular model updates based on actual failure data

- Performance tracking and ROI measurement

- Expansion to additional equipment types based on success metrics

Recommended Tools:

- IBM Maximo Application Suite: Comprehensive asset management with AI-powered insights

- GE Digital Predix: Industrial IoT platform with predictive maintenance capabilities

- Siemens MindSphere: Cloud-based IoT operating system for predictive analytics

3. Inventory Management Automation

The Challenge: Balancing inventory levels to avoid stockouts while minimizing carrying costs requires constant attention and often results in either excess inventory or production delays.

AI Solution: Intelligent inventory systems that automatically optimize stock levels based on real-time demand signals, production schedules, and supply chain conditions.

Step-by-Step Implementation Process:

Step 1: Data Consolidation

- Integrate sales data, production schedules, and supplier lead times

- Connect warehouse management systems with production planning

- Establish real-time inventory tracking across all locations

Step 2: Demand Forecasting Setup

- Deploy AI models for demand pattern recognition

- Implement seasonal and trend analysis capabilities

- Configure multi-variable forecasting including external factors

Step 3: Automated Inventory Controls

- Set up dynamic safety stock calculations based on demand variability

- Configure automatic reorder points adjusted by AI predictions

- Implement smart allocation algorithms for multi-location inventory

Step 4: Performance Monitoring

- Track inventory turnover rates and service level improvements

- Monitor cost reductions from optimized inventory levels

- Continuous model refinement based on forecast accuracy

Recommended Tools:

- Microsoft Dynamics 365 Supply Chain Management: AI-driven inventory optimization

- Manhattan Associates: Warehouse management with intelligent inventory controls

- Logility: Advanced planning and optimization for inventory management

The ROI of Manufacturing AI Automation

Manufacturers implementing AI automation are seeing remarkable returns on investment. Companies report:

- Reduced downtime by 35-50% through predictive maintenance

- Inventory cost reductions of 20-30% via optimized stock levels

- Supply chain efficiency improvements of 15-25% through intelligent planning

- Overall equipment effectiveness (OEE) increases of 10-20%

These improvements compound over time, with many manufacturers achieving full ROI within 12-18 months of implementation.

Implementation Strategy for Success

Start with High-Impact, Low-Complexity Areas

Begin with processes that have clear ROI potential and existing data infrastructure. Predictive maintenance often provides the quickest wins due to immediate cost savings from avoided failures.

Ensure Data Quality and Integration

AI automation is only as good as the data feeding it. Invest in data cleaning, standardization, and integration before deploying AI solutions.

Plan for Change Management

Successful AI automation requires workforce adaptation. Provide comprehensive training and clearly communicate how AI enhances rather than replaces human expertise.

Scale Gradually

Start with pilot programs, measure results, and expand successful implementations across similar processes and equipment.

The Future of Smart Manufacturing

By 2028, 65% of major manufacturers will use AI agents working alongside design and simulation tools to continuously validate configurations and optimize operations. The factories of 2026 won't just be automated: they'll be intelligent, adaptive, and self-improving.

Manufacturers who act now to implement AI automation will have a significant competitive advantage as the industry continues to evolve. The question isn't whether to adopt AI automation, but how quickly you can implement it effectively.

Ready to Transform Your Manufacturing Operations?

At Virtual Nexgen Solutions, we specialize in helping manufacturers implement AI automation strategies that deliver measurable results. Our team of AI and automation experts can assess your current operations, identify the highest-impact opportunities, and guide you through successful implementation.

Whether you're looking to reduce downtime through predictive maintenance, optimize your supply chain, or streamline inventory management, we have the expertise and tools to help you succeed.

Take the first step toward smarter manufacturing. Book a free 30-minute consultation with our manufacturing AI specialists and discover how AI automation can transform your operations.

Don't let your competitors get ahead: the future of manufacturing is happening now, and it's powered by AI automation.